When it comes to sawing aerospace alloys with a band saw it can prove to be the most challenging of all materials, due to their high nickel content.

An example of the most common Aerospace alloys are:

Inconel

Titanium

Duplex

Stainless Steel

Aluminium

Waspalloy

Hastalloy

Other Nickel based products

For most applications, we would recommend using a Roentgen carbide tipped band saw blade.

For some of these applications our M51 Bi-metal band saw blades with the correct feed and speed rates can handle these materials, but if the incorrect speeds are implemented this can have a detrimental impact on the life of the blade.

We would recommend the following blades for cutting nickel based alloys:

Each customer has unique specifications and machine, for more information on sawing Aerospace alloys please contact us on 024 7661 0907 or email us on sales@krsaws.co.uk .

Companies manufacturing aluminium castings use band saw blades for sawing the risers off the castings after they have been produced.

This process can be challenging due to the aluminium castings abrasive nature caused by sand and the high band speeds used when sawing the risers off.

Our high-performance carbide tipped HM-Titan Alu2 and Alu3 band saw blades are designed to withstand high band speeds.

Roentgens bi-alfa WS Alu band saw blade features a wide kerf and aggressive tooth angle, this facilitates a more efficient chip flow, reducing binding, clogging and promotes a longer blade life when sawing aluminium castings.

We are one of the only companies in Europe to stock the 27mm x 1mm band saw blade for cutting aluminium castings. The extra 0.2mm increases the thickness and stability of the blade and reduces the chances of breakages.

The new high alloy backing strip also helps to reduce the fatigue on the blade caused when bending.

Roentgens unique tooth geometry improves the surface finish even in the toughest of environments.

Blade recommendation for aluminium castings:

HM Titan Alu2

HM Titan Alu3

Cobalt WS Alu

Each customer has unique specifications and machine, for more information on Aluminium Castings Blades please contact us on 024 7661 0907 or email us on sales@krsaws.co.uk .

Sawing steel tube has always been a massive focus for our parent companies Kinkdelder and Roentgen.

More so Kinkelder as they manufacture a wide variety of HSS and Carbide Tipped circular saw blades to suit different steel and stainless steel tube applications across the globe.

With our extensive range of stock at KR saws we have a blade to suit all applications and machines:

HSS CIRCULAR SAW BLADES

- Kinkelder Alpha – This blade is mainly used in engineering companies and fabricators, because the machines are manual with no control over feed rates that wouldn’t tend to generate a lot of heat.

- Kinkelder coated EC3000 – A versatile and cost effective PVD coated blade. This coating helps to protect against heat and reduce wear, suitable for semi-automatic and fully automatic circular saw machines cutting steel and stainless steel with a tensile strength of up to 600 N/mm2.

- Kinkelder power 2000 – This circular saw blade is ideal for cutting stainless steel on high production circular saw machines such as an RSA, Bewo or Adige. This blade has a superior surface finish and PVD coating to minimise vibration and burr, which is why the Power blade is the best HSS circular saw blade for steel tube.

- Kinkelders HSS diameters start from 225mm up to 600mm.

CARBIDE TIPPED CIRCULAR SAW BLADES

- Kinkelder CX3 – This blade has been specially developed for sawing steel tube on high product automatic circular saw machines such as a Mega, Rattunde, RSA, Eisle Behringer or Tsune. This blade has the ability to cut at much higher production rates than HSS circular saw blades.

- Kinkelder CX 4 – Sawing stainless steel tube has become a challenge for many companies due to the high nickel content that resides within the tube, but the CX4 enables sawing speeds of up to 100% doubling production rates.

- Kinkelder TubeMaster – There are 2 varieties of this blade, one for stainless steel and the other for carbon steel. Both of these blades have a new body design and improved carbide grade and geometry, this has allowed Kinkelder to develop the perfect solution for cutting tube with a TCT circular saw blade on tube mills using flying and orbital saws such as MTM, OTO mills and linsinger.

BANDSAW BLADES

- Roentgen Profile Band Saw – The interrupted nature of steel and stainless steel tube can have a detrimental effect on the blades tool life, but the uniquely reinforced tooth profile on this blade produces a superb cut whilst reducing vibration. The additional strengths in the back of the tooth decreases the chances of teeth stripping, making it the perfect band saw blade for steel tube.

For videos of tube sawing please visit our Saw Blade video centre.

If the saw blade you require does not appear on this page and you require more information please contact us

For more information, technical advice or prices please call us on 024 7661 0907 or email us on sales@krsaws.co.uk .

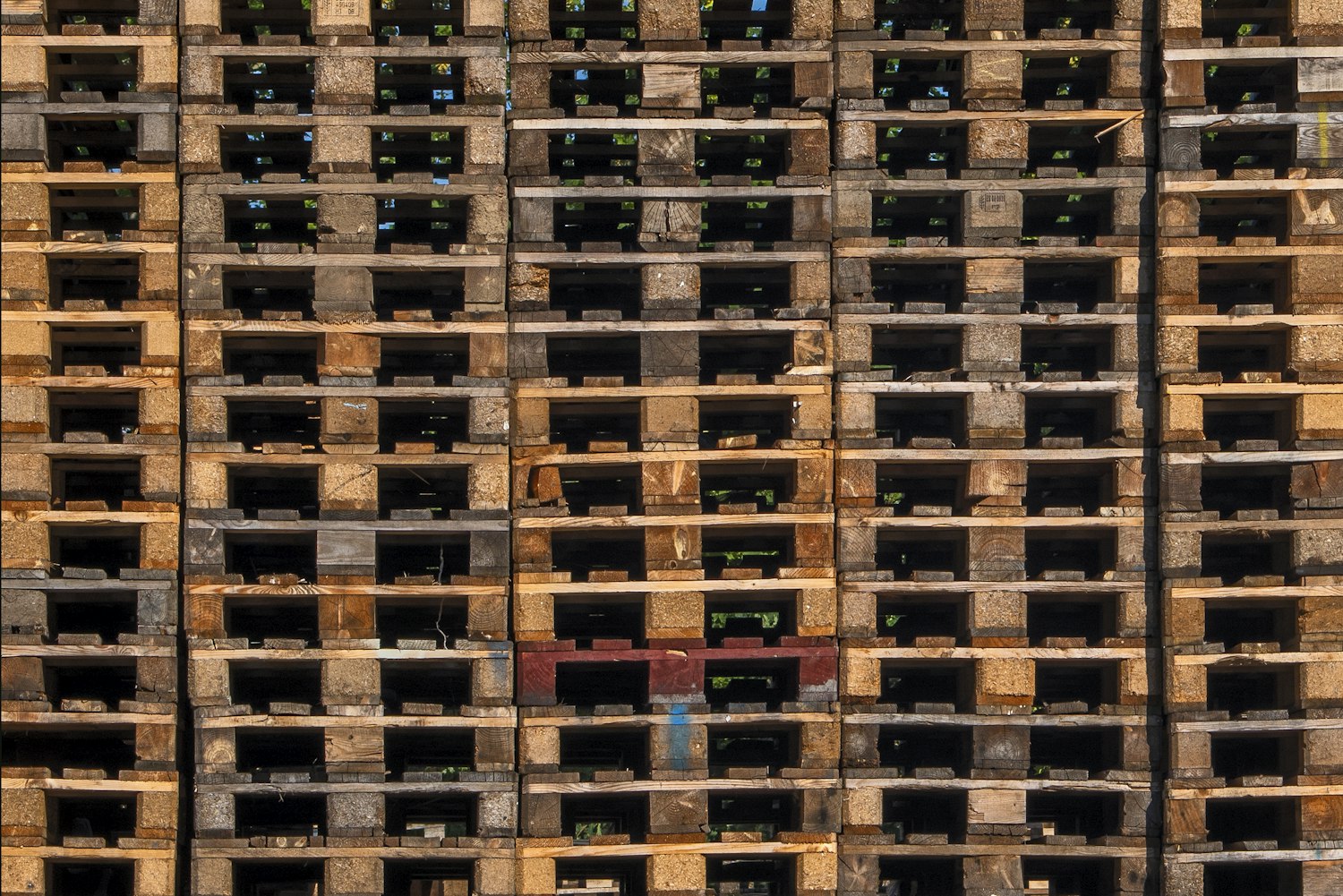

Our specially designed M42 PalletMaster band saw blade is the ideal solution for pallet yards.

Despite the fact that pallets are predominantly wood they come with their sawing challenges due to the nails that reside within the pallets.

Roentgen have developed a band saw blade which is nail resistant and can therefore reduce the chances of teeth stripping.

We weld our blades to suit all pallet band saw machines, the most popular manufacturers are green machine and warrior who we are an approved supplier for.

The most common sizes for a pallet band saw blade is 6070mm x 34mm x 5/8 TPI.

We supply pallet yards all over the U.K. and any orders received before 12pm are delivered next day and orders over £150 are delivered free of charge.

For prices and more information please call us on 024 7661 0907 or email sales@krsaws.co.uk .

Structural steel comes in many shapes, sizes, grades and dimensions so there is rarely one band saw blade to suit all unless you’re cutting the same section continuously.

Finding the best compromise is often the ideal solution for structural steel stock holder and fabricators.

This is when our dedicated sales engineers can help you to find the best blade and tooth pitch for your requirements.

With our extensive stock range we can supply a variety of saw blades to suit your application and machines;

BAND SAW BLADES FOR STRUCTURAL STEEL

- TheProfile band saw blade is suitable for sawing interrupted sections such as steel beams, steel angle and steel box.

- TheProfile wide set (WS) band saw blade Is an ideal for sawing high grade steel beams (e.g. 355) with high tensile stresses, the extra kerf in the tooth helps to prevent ‘trapping’ or ‘binding’.

- StandardM42 band saw blade is an ideal solution for fabricators who saw steel sections and flat steel bar.

CIRCULAR SAW BLADES FOR STRUCTURAL STEEL

- Kinkelder Alpha circular saw blades are the standard blade for cutting all structural steel sections and steel tubes with a tensile strength of up to 700 N/mm2

- Kinkelder EC 3000 circular saw blades are suitable for thicker wall steel box sections and steel tubes on high production machines that can generate significant amounts of heat, the coating helps to prevent tooth damage and wear.

SEGMENTAL SAW BLADES FOR STRUCTURAL STEEL

- Kinkelder Segmental saw blades have sections of teeth that can be easily replaced if the teeth are damaged, making the blades longer lasting.

- They have become less common in recent years since the rise of the HSS blade but still remain a staple in the structural steel industry.

- We can supply a wide variety of sizes ranging from 250 mm to 1610 mm with various different tooth pitches

- Segmental blades are used to cut all types of structural steel